Valves – The Overlooked Component of a Cylinder

Making advancements in valve technology with RPVs

Valves are one of the most purchased components in the gas industry, AND one of the most overlooked.

Practically every cylinder or tank comes equipped with some type of valve. Retest facilities stock thousands of valves for quick replacement. And gas distributors store multiple boxes of valves on their shelves for swapping out faulty or broken ones.

Despite the large volume, this aspect of the cylinder business is often an afterthought. This is particularly surprising given that valves are the most likely component of a cylinder to fail. Leaks using safety inlets, CGA connectors, and overuse contribute to valve malfunctions in the field every day.

As one of the leading suppliers of gas cylinders and cryogenics, Cyl-Tec processes thousands of valve orders for gas distributors and fill plants. They also work directly with gas distributors and fill plant operators in the field, so they hear what works and what does not work.

Over time, Cyl-Tec came to realize that they could really help customers to better understand the different sizes, types, and designs of valves available, and to choose the proper valve for each application.

New advances in valve designs

Valves have been in use for hundreds of years with steady technological progressions, but over the last few decades, there have been some important advances worth noting.

Valves have been in use for hundreds of years with steady technological progressions, but over the last few decades, there have been some important advances worth noting.

The packed style valves have been mostly replaced by the easier to operate O-ring style valve for standard industrial gas applications. Tied diaphragm style valves have become the standard for high-end specialty gas laboratories. Many valve manufacturers have used ergonomic principles to improve their valve designs and markings helping to make fill plant technician’s life much easier and safer.

Precision CNC machining of the valve inlet and outlet threads, proper Teflon® tape application, and choosing the correct inlet thread specification for the cylinder are vitally important to prevent neck leaks. Cyl-Tec utilizes automatic taping machines when installing tapered thread style valves. These machines apply the Teflon® tape consistently and with the correct thickness and location to minimize potential neck leaks.

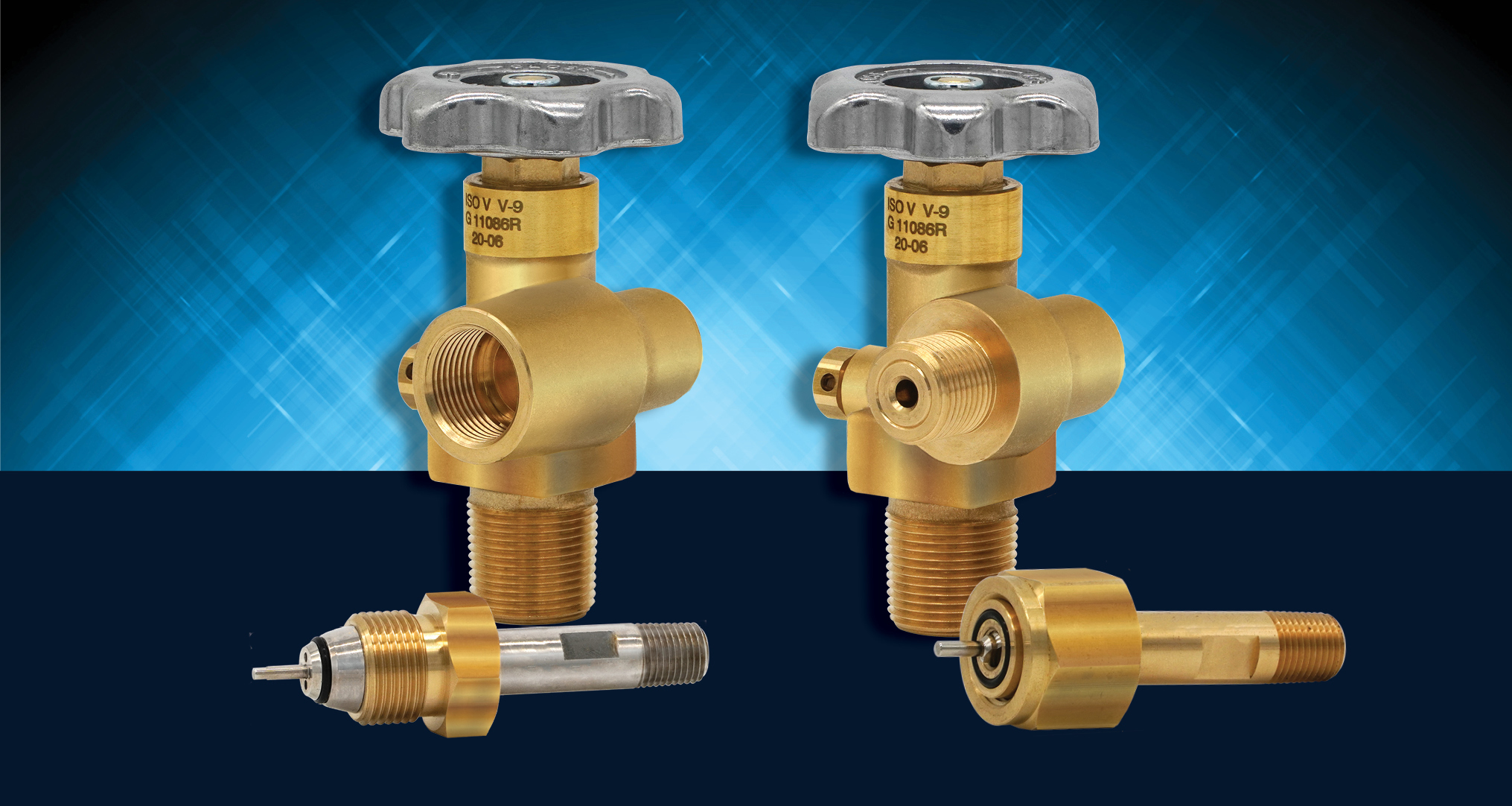

Valves with special features, such as Valve Integrated Pressure Regulators (VIPR) and Residual Pressure Valves (RPV), have also become increasingly popular and continue to evolve.

Residual Pressure Valves – A Practical Solution

Residual Pressure Valves are one of the more relevant recent advances in cylinder valve design and are worth mentioning in more detail. RPV benefits include: 1) prevention of back flow contamination, 2) maintenance of high gas quality, 3) reduction of internal cylinder maintenance, and 4) improvement of cylinder lifespan.

Residual Pressure Valves are one of the more relevant recent advances in cylinder valve design and are worth mentioning in more detail. RPV benefits include: 1) prevention of back flow contamination, 2) maintenance of high gas quality, 3) reduction of internal cylinder maintenance, and 4) improvement of cylinder lifespan.

In Europe, about 80% of all gas cylinder valves are currently RPVs. In the U.S. however, RPVs are used only in certain applications and are not as widespread domestically… yet.

Residual Pressure Valves are available for a wide variety of gas service like oxygen, argon, helium, hydrogen, carbon dioxide, and specialty gas mixtures and are suitable for use up to 300 bar working pressure.

The key concept of an RPV is that the valve retains a small positive pressure inside the gas cylinder or tank even if the valve is inadvertently left open. Gas distributors already using RPVs have been able to minimize or eliminate the high cost of purging, evacuation, and internal cleaning of cylinders.

Beverage grade CO2 presents a good opportunity for using RPVs. Despite the warning notices on CO2 gas cylinders and tanks, the end users rarely follow good operating practices, like leaving a small positive pressure in the gas cylinder or closing the cylinder valve after use. This poor practice can allow contaminants to enter the cylinder preventing the filling of certified beverage grade CO2 as well as cause corrosion inside the cylinder.

With the industry’s push to make certain that certified beverage grade CO2 is delivered to the end user, cylinder fillers are turning to RPVs to provide their customers with beverage grade CO2 in clean cylinders.

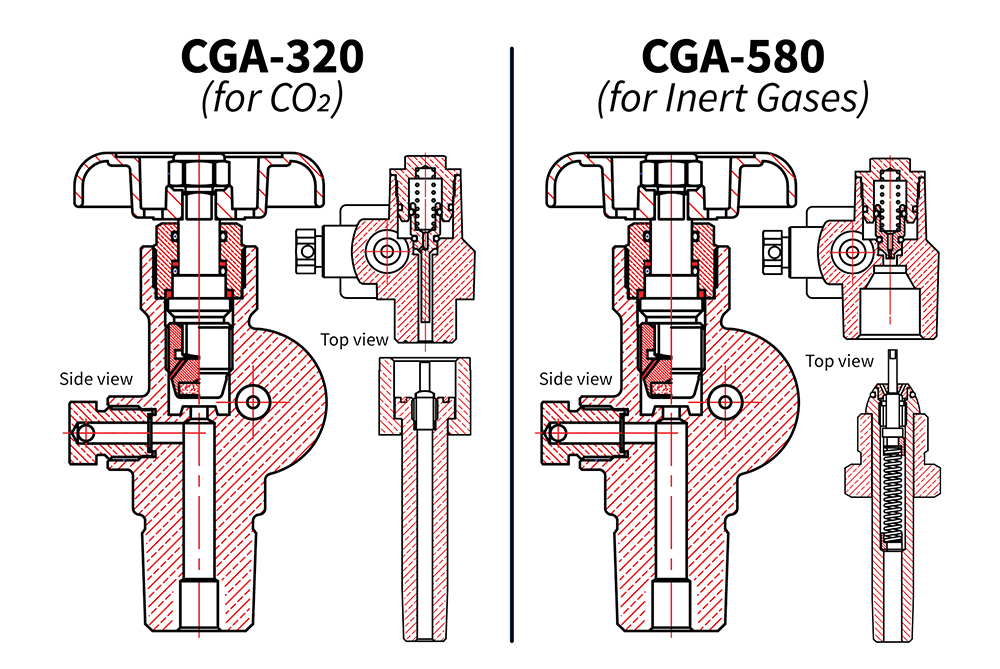

How Residual Pressure Valves work

A Residual Pressure Valve is a standard valve with the addition of a residual pressure unit. The additional unit contains these features: an O-ring that seals the housing into the valve body, a spring, a piston with quad ring, and a small O-ring that seats the residual pressure unit against the spring force.

A Residual Pressure Valve is a standard valve with the addition of a residual pressure unit. The additional unit contains these features: an O-ring that seals the housing into the valve body, a spring, a piston with quad ring, and a small O-ring that seats the residual pressure unit against the spring force.

When the valve is in the closed position, the piston is under spring force against the valve body sealing surface and the small O-ring seals the outlet off against the atmosphere.

When the valve is opened, the contents of the cylinder flow through the valve to the front side of the piston. If the force exceeds the spring load, the piston is forced backward from the sealing surface into the housing by compressing the spring, allowing the gas contents to flow out of the cylinder through the outlet.

If the cylinder pressure ever falls below 1-5 bar, the spring force closes the piston against the valve seat, resulting in a retained residual pressure in the cylinder at the end of its discharge cycle.

This retained residual pressure prevents a cylinder from ever becoming completely empty, thus ensuring less contamination inside the vessel.

Cyl-Tec – One Resource. Zero Headaches.®

If you have any questions about RPVs, Cyl-Tec would be glad to help. Cyl-Tec provides practical guidance on specific applications and solutions for RPVs as well as other types of cylinder valves. Their Grand Valve™ line offers popular CGA models including harder-to-find models, such as oversized or specialty valves.

Cyl-Tec’s mission has always been to provide the best lead time by keeping gas cylinder and cryogenic stock on-hand in their Aurora, Illinois warehouse. This same approach has been taken with maintaining a large valve inventory as well – to be the one resource for gas packaging needs.